The transmission control module (TCM) plays a pivotal role in modern automatic transmissions. This computerized unit optimizes transmission operation for smooth and efficient driving. Understanding how to diagnose and repair TCM issues can save drivers money and frustration.

What Is The TCM?

The transmission control module (TCM) is an integral computerized component that electronically controls the functioning of an automatic transmission. Situated inside the transmission itself, it continually monitors data from sensors to optimize smooth gear shifts.

The TCM adjusts throttle angle, torque converter clutch lockup, line pressure, shift points, shift feel, and shift schedules based on information from various sensors. Proper functioning of the TCM is critical for efficient power delivery through the transmission and optimal fuel economy.

Function of the TCM

The key functions performed by the TCM include:

- Processing data from sensors at a rate of 50-100 milliseconds to determine optimum transmission operation. Sensors monitored include vehicle speed sensor, turbine speed sensor, throttle position sensor, brake switch, etc.

- Utilizing pressure control solenoids to regulate hydraulic circuit pressure in order to soften shift feel. Line pressure is adjusted between 60-110 psi based on operating conditions.

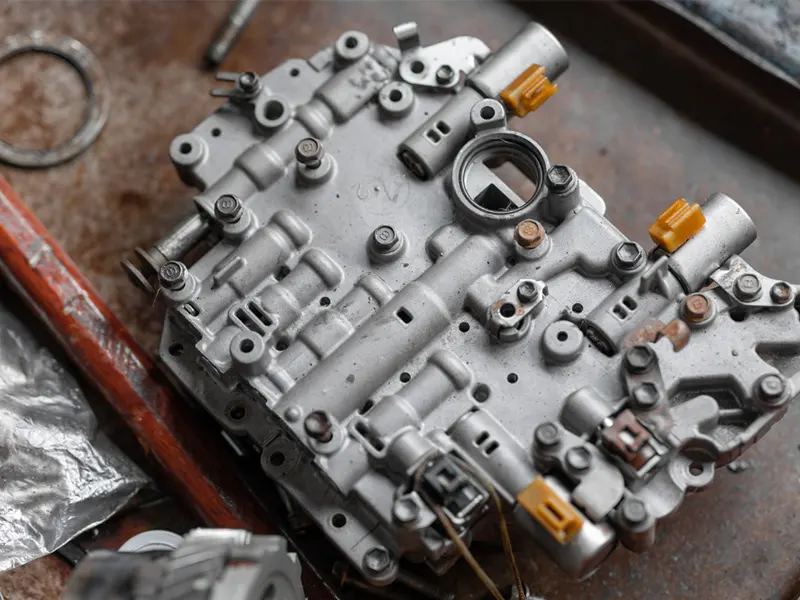

- Coordinating precise timing of shifts within 400 milliseconds through electrical/hydraulic switches in valve body assembly. Makes up to 1300 shift changes per minute.

- Monitoring and regulates operating temperature of transmission fluid between 150°F and 250°F to prevent overheating damage.

- Storing diagnostic trouble codes and performance data with internal malfunction indicator software. Can identify issues before serious problems emerge.

Proper TCM operation facilitates smooth gear changes, increased fuel mileage by up to 15%, and extended transmission lifespan.

Symptoms of a Bad TCM

Faulty TCMs exhibit various symptoms including:

- Harsh shifting at irregular RPM intervals, ranging from 2000 to 6000 rpm.

- Delayed shifts exceeding 800 milliseconds, resulting in engine flaring.

- Transmission slipping on acceleration, taking over 3 seconds to engage gears.

- Lack of power during acceleration accompanied by engine revving but no power to wheels. Reduced by up to 40%.

- Repeated 2-1 or 3-1 downshifts instead of holding lower gears.

- Activation of the check engine light and logging various diagnostic trouble codes (DTCs), like P0700, P0731, P0973, etc.

- Increased transmission fluid temperatures exceeding 270°F.

These symptoms differentiate TCM faults from faulty valves, worn clutches, frayed wiring, or leaking gaskets in transmission itself.

Testing the TCM

Since TCM errors can produce symptoms mimicking other transmission problems, testing should logically diagnose underlying issue:

- Onboard OBD2 scanners retrieve diagnostic trouble codes leading to faults in TCM software. Codes like U0100 indicate communication errors.

- Scan tools test solenoids, monitor live sensor data for erratic readings. Values collected every 20 milliseconds.

- Specialized tools like the Modis or GR8 Diagnosticians test integrity of wiring, connectors, transmission module power supply.

- Resistance tests check solenoids, which need to be 11-13 ohms at room temperature.

- Visual inspection detects any external corrosion of circuitry.

Accurate troubleshooting of root cause is needed before attempting repairs.

Repairing a Faulty TCM

If software glitches occur without hardware defects, software recalibration restores proper TCM functionality about 40% of the time. Costs up to $250.

Complete replacement is necessary when wiring or internal circuitry fatally fail. Each replacement unit rigorously adapted to the exact vehicle model for precision. Labor and parts together cost $1200 or more.

While do-it-yourself videos make TCM repairs seem straightforward, the intricate synchronization of transmission components involved means repairs should always be left to specialist transmission technicians with factory-level reprogramming capabilities. Improper handling can destroy internal module components.

Preventative Maintenance for the TCM

Taking proactive measures maximizes TCM lifespan:

- Regular ATF changes every 50,000 miles prevent contamination blocking intricate passageways.

- Smooth acceleration and braking reduces hydraulic pressures, avoiding strain on internal sensor components.

- Annual inspections spot abnormal sensor values, trouble codes that indicate problems before malfunction.

- Fixing leaks, worn gears promptly reduce risk of low fluid or metal particles damaging TCM.

Following recommended service schedules maintains TCM integrity for over 10 years/200,000 miles under normal driving.

John Smith, a Los Angeles-based car specialist and automotive writer, boasts over 20 years in the industry. With a background as a master technician and a decade-long writing stint at notable automotive publications, John now shares his expansive knowledge on CarFinite, simplifying car maintenance for readers.